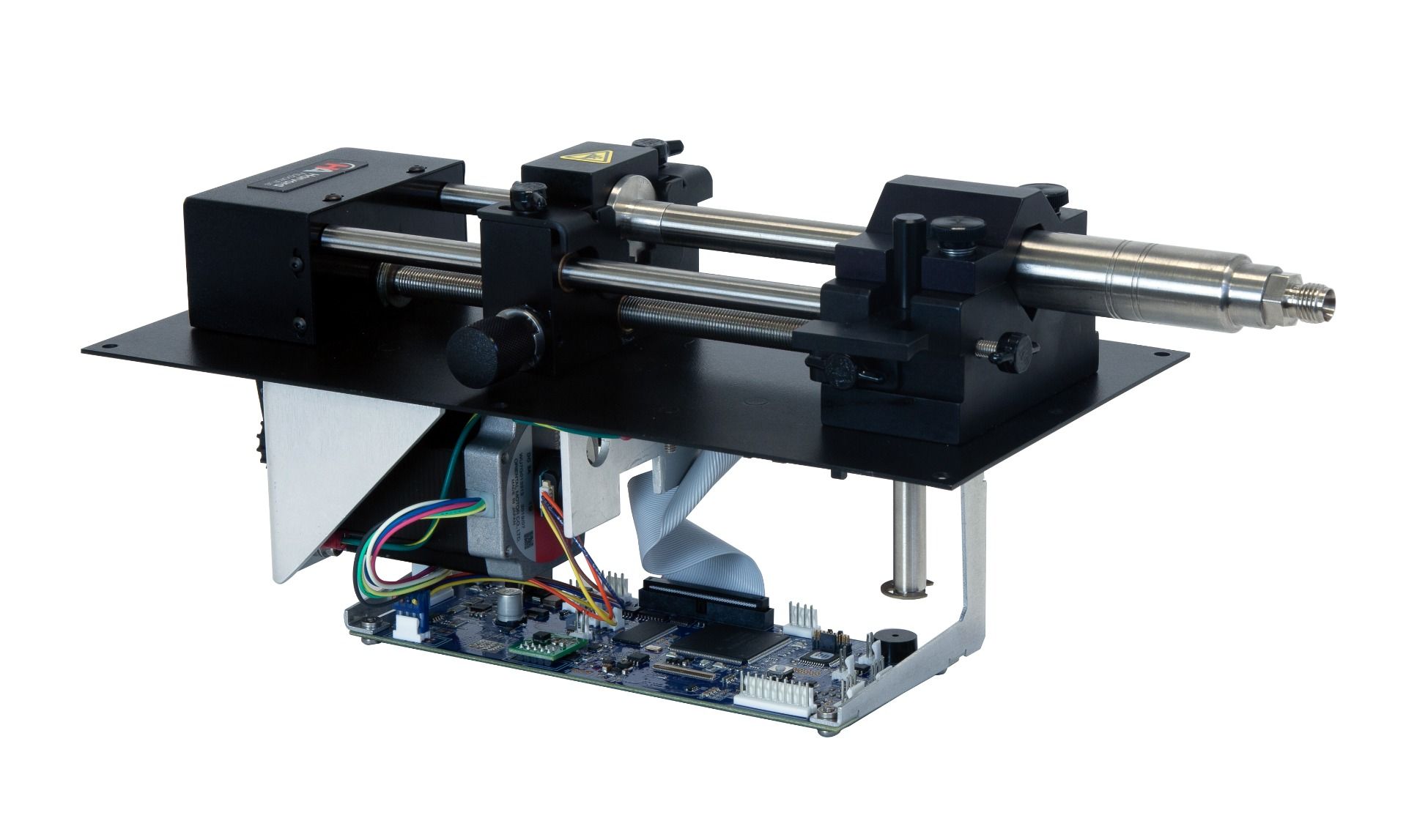

PHD ULTRA™ 4400 OEM Open Baseplate Syringe Pump Module

As an Original Equipment Manufacturer (OEM), your success depends on your reputation. And your reputation is literally built on your ability to consistently deliver reliable, quality products at competitive prices.

When it comes to manufacturing pumps, it is essential that you have best-in class components that offer flexibility, so you can satisfy your varying application needs. And, it is critical that the mechanisms you use consistently deliver the precise, accurate and reliable flow that your customers demand.

Wouldn’t it be nice to partner with a reputable vendor who could provide both proven, state-of-art mechanisms and the support you need to easily and affordably develop your fluidics analysis systems?

Harvard Apparatus has a wealth of experience in the development and manufacture of specialized fluidic systems. With a full line of OEM pumps, we offer the broadest selection of fluidics components, systems and specials. Whether your requirement is for a single order/one-time study or you need a fluidic module to integrate into your systems, we have the solution. And, we can readily customize to best meet your application needs.

Cited in thousands of studies across a myriad of applications, Harvard Apparatus pumps are best-in-class. In fact, from pre-clinical disease to microfluidic disease modeling to drug creation and drug testing, our syringe pumps are already relied upon globally by tens of thousands of scientists to reach their research objectives.

The PHD ULTRA™ 4400 is the solution for your most demanding high pressure fluidics applications. This pump represents the latest technology in syringe pumps and was developed utilizing the feedback of the world's largest populations of syringe pump users. This syringe pump platform has superior mechanical drive mechanism and syringe holding mechanics to achieve the highest performance of any syringe pump.

The PHD ULTRA™ 4400 is a single syringe infusion/withdrawal programmable syringe pump with a flow rate range of 3.06 pl/min to 216.0 ml/min with 200 lb of adjustable force across the entire flow rate range.

This innovative high pressure syringe pump component has a footswitch input, RS-232 and USB serial ports for computer control, RS-485 ports for daisy chaining pumps and Digital I/O for external control via an independent computer or device.

As an Original Equipment Manufacturer (OEM), your success depends on your reputation. And your reputation is literally built on your ability to consistently deliver reliable, quality products at competitive prices.

When it comes to manufacturing pumps, it is essential that you have best-in class components that offer flexibility, so you can satisfy your varying application needs. And, it is critical that the mechanisms you use consistently deliver the precise, accurate and reliable flow that your customers demand.

Wouldn’t it be nice to partner with a reputable vendor who could provide both proven, state-of-art mechanisms and the support you need to easily and affordably develop your fluidics analysis systems?

Harvard Apparatus has a wealth of experience in the development and manufacture of specialized fluidic systems. With a full line of OEM pumps, we offer the broadest selection of fluidics components, systems and specials. Whether your requirement is for a single order/one-time study or you need a fluidic module to integrate into your systems, we have the solution. And, we can readily customize to best meet your application needs.

Cited in thousands of studies across a myriad of applications, Harvard Apparatus pumps are best-in-class. In fact, from pre-clinical disease to microfluidic disease modeling to drug creation and drug testing, our syringe pumps are already relied upon globally by tens of thousands of scientists to reach their research objectives.

The PHD ULTRA™ 4400 is the solution for your most demanding high pressure fluidics applications. This pump represents the latest technology in syringe pumps and was developed utilizing the feedback of the world's largest populations of syringe pump users. This syringe pump platform has superior mechanical drive mechanism and syringe holding mechanics to achieve the highest performance of any syringe pump.

The PHD ULTRA™ 4400 is a single syringe infusion/withdrawal programmable syringe pump with a flow rate range of 3.06 pl/min to 216.0 ml/min with 200 lb of adjustable force across the entire flow rate range.

This innovative high pressure syringe pump component has a footswitch input, RS-232 and USB serial ports for computer control, RS-485 ports for daisy chaining pumps and Digital I/O for external control via an independent computer or device.

| Specifications | 70-3610 |

| Accuracy | ± 0.35% |

| Syringe (Min./Max.) | 0.5 µl / 140 ml single |

| Flow Rate: | |

| Minimum (0.5 µl syringe) | 3.16 pl/min |

| Maximum (140 ml syringe) | 215.8 ml/min |

| Display | None |

| Non-Volatile Memory | Stores all settings |

| Connectors: | |

| RS-485 | IEEE-1394, 6 pos |

| USB | Type B |

| I/O & TTL | 15-pin D-Sub Connector |

| Footswitch | Mini phono jack |

| RS-232 (option) | RJ-11 |

| Linear Force (Max) | 91 kg (200 lb) @ 100% Force Selection |

| Drive Motor | 0.9° Stepper Motor |

| Motor Drive Control | Microprocessor with 1/16 microstepping |

| Microsteps/revolution of lead screw |

6.400 |

| Step Resolution | 0.164 µm/µstep |

| Step Rate: | |

| Minimum | 27.5 sec/µstep |

| Maximum | 52 µsec/µstep |

| Pusher Travel Rate: | |

| Minimum | 0.15 µm/min |

| Maximum | 159.00 mm/min |

| Input Power | 12 to 30 VDC, 50 W (30V recommended) |

| Power Supply | Not included |

| Dimensions | 11.9 x 6.0 x 6.5 (30.2 x 15.2 x 46.6 cm) |

| Weight | 3.86 kg (8.50 lb) |

| Atmospheric Conditions | |

| Operating Temperature | 4°C to 40°C (40°F to 104°F) |

| Storage Temperature | -10°C to 70°C (14°F to 158°F) |

| Storage Humidity | 20% to 80% RH, non condensing |

| Method of Operation | Continous |

| Classification | Class I |

| Pollution Degree | 1 |

| Installation Category | II |

| Supplier Name | Harvard Appartus |

| Supplier Address | 84 October Hill Rd., Holliston, MA 01746 |

| Supplier Phone Number | (508) 893--8999 |

| Regulatory Certifications | WEEE, EU RoHS |